Rapid Prototyping

Functional prototypes and design validation to accelerate product–market fit — fast, testable, and production-aware.

Typical response time: within 24 hours.

Methods & Materials

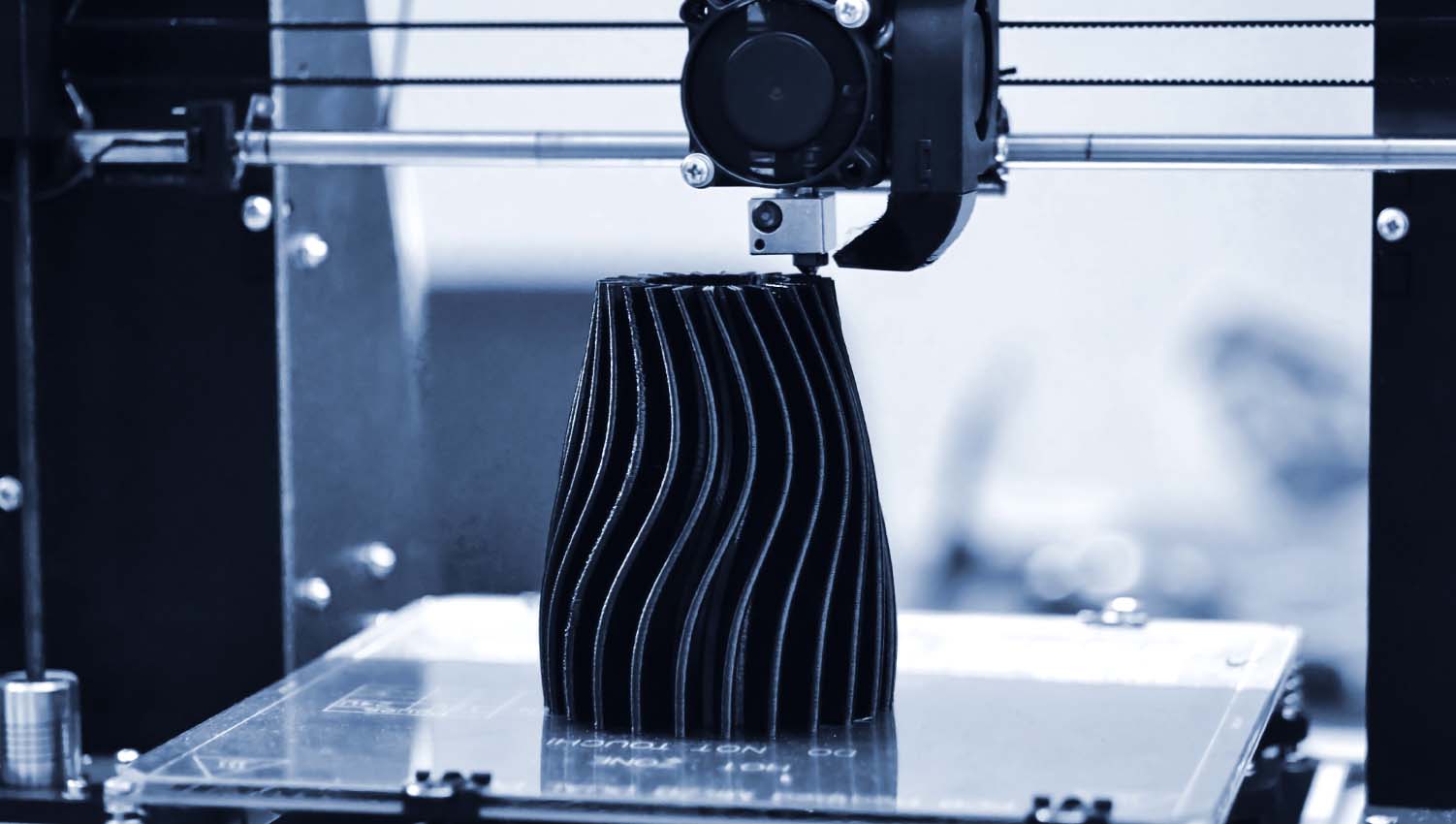

FDM/SLA/SLS

Visual and functional plastics with fine detail.

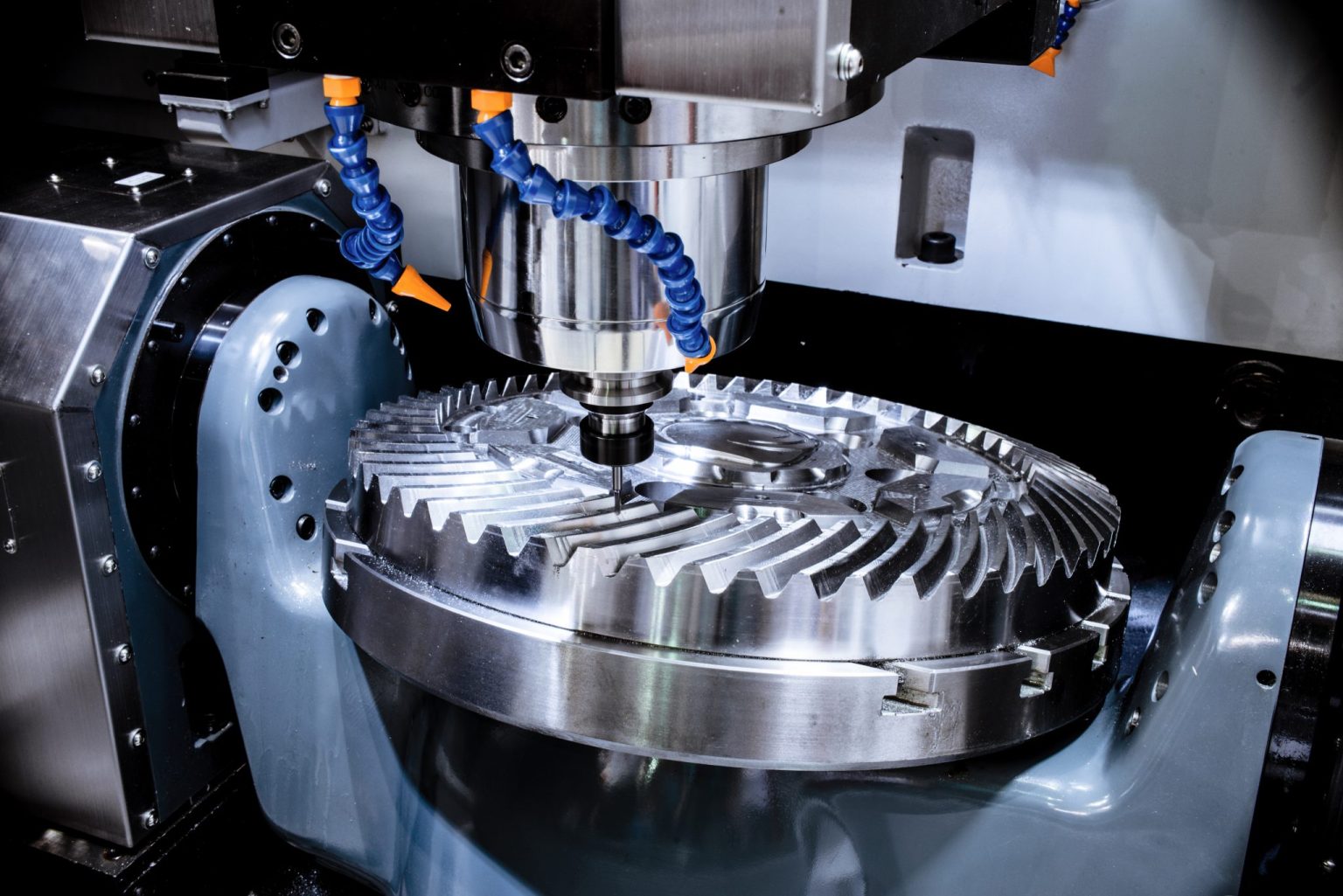

CNC Machining

Metals and engineering plastics with tight tolerances.

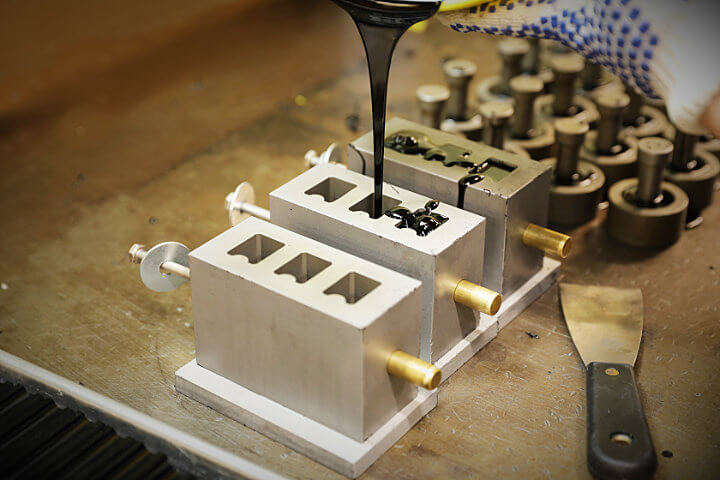

Urethane Casting

Short runs from silicone tools for market tests.

Sheet Metal

Rapid brackets and enclosures.

Finishing

Paint, texture, inserts, and assembly.

Test & Fit

Gauge checks, tolerances, and basic performance tests.

Case Study — Prototype to Pilot in 12 Days

Challenge: Investor demo deadline

Solution: SLA housings + CNC internals

Outcome: Demo-ready units in 12 days, funding secured

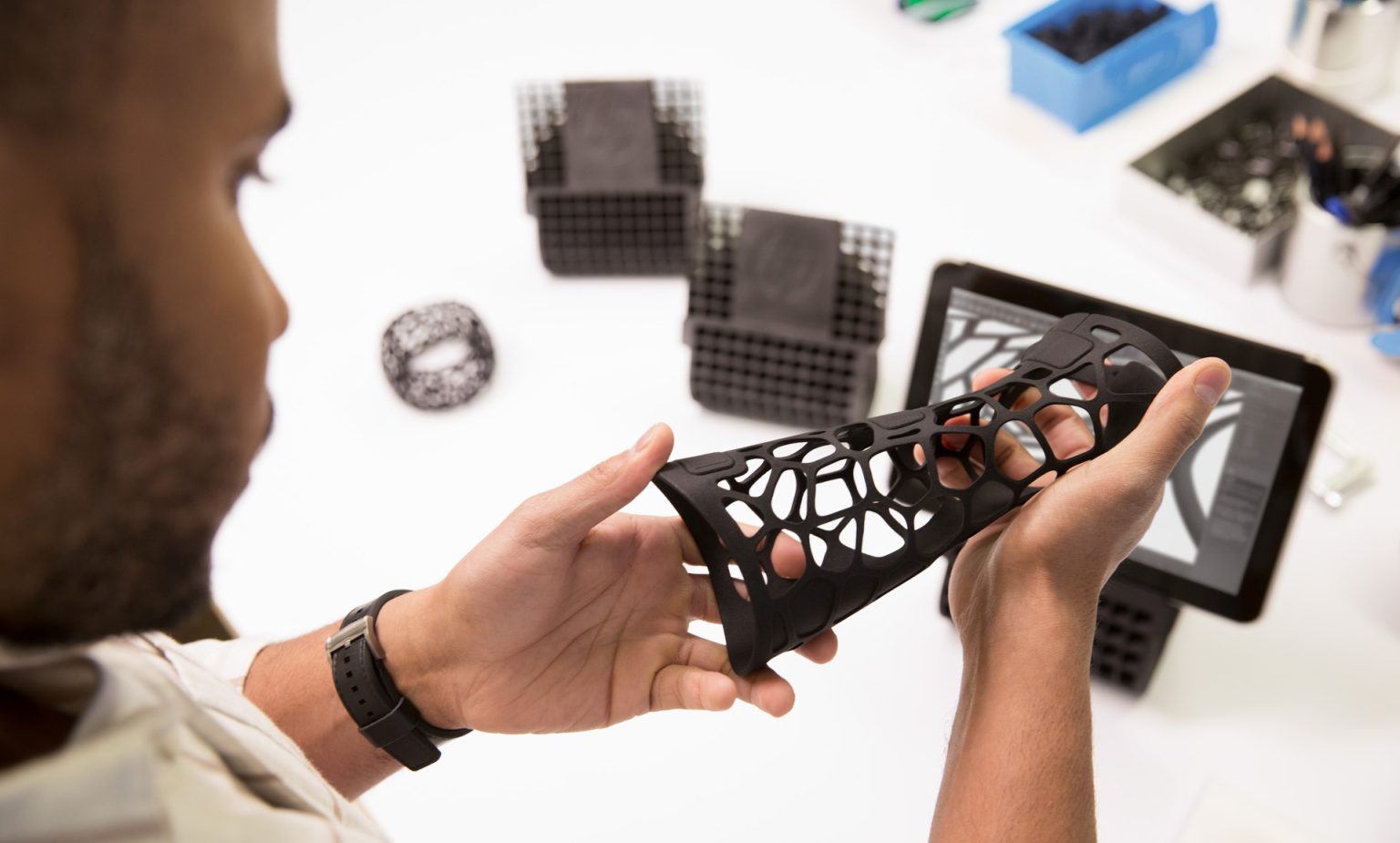

Functional, Not Just Visual

Mechanical properties suitable for real testing.

Production-Aware

DFM feedback to shorten the path to tooling.

Fast Turnarounds

Parts in days; pilot builds in 1–2 weeks.

FAQs

What’s the fastest turnaround?

Simple parts: 2–3 days. Assemblies: 1–2 weeks.

Can you match production materials?

We’ll advise the closest prototyping analogs to your target resin/metal.

Do you help with tolerances/fit?

Yes—DFM notes and fit checks are standard.

Can you assemble working units?

On request—light assembly and finishing available.

Ready to bring your product or process to life?

Let’s discuss your project today — from prototypes to production-scale automation.