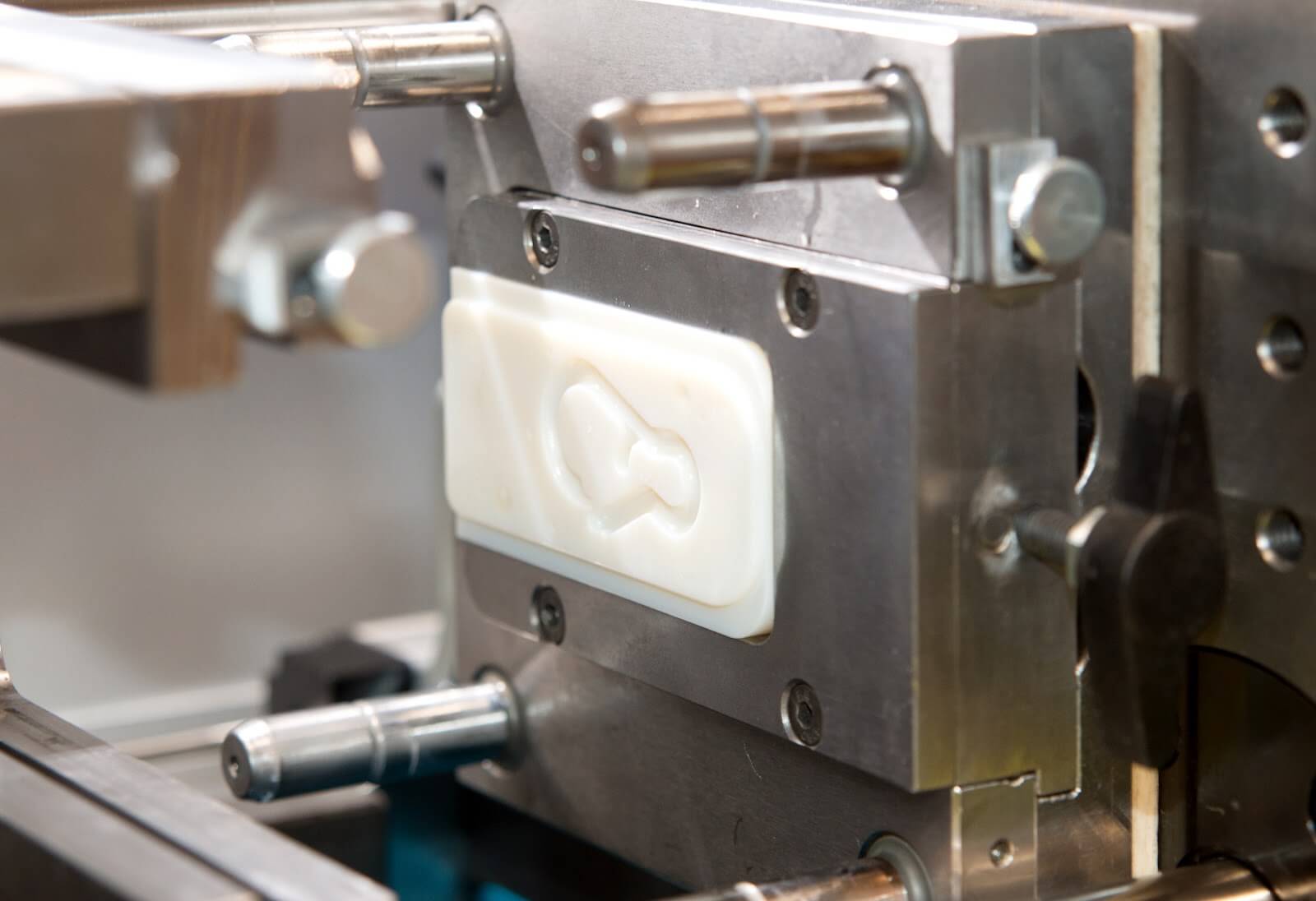

Rapid Injection Moulds

Production-grade tooling engineered for speed, cost per part, and durability — built to run reliably with minimal downtime.

Typical response time: within 24 hours.

Tooling Capabilities

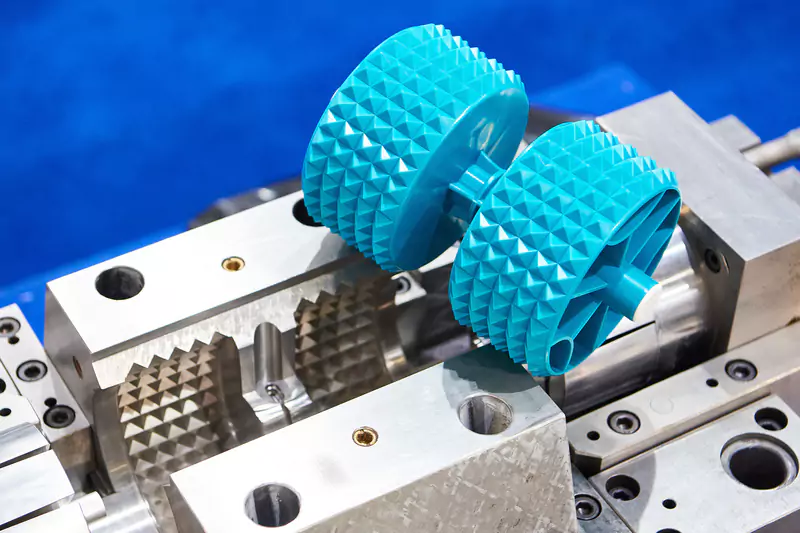

Gate & Runner Design

Hot/cold runner layouts to minimize shear and balance fill.

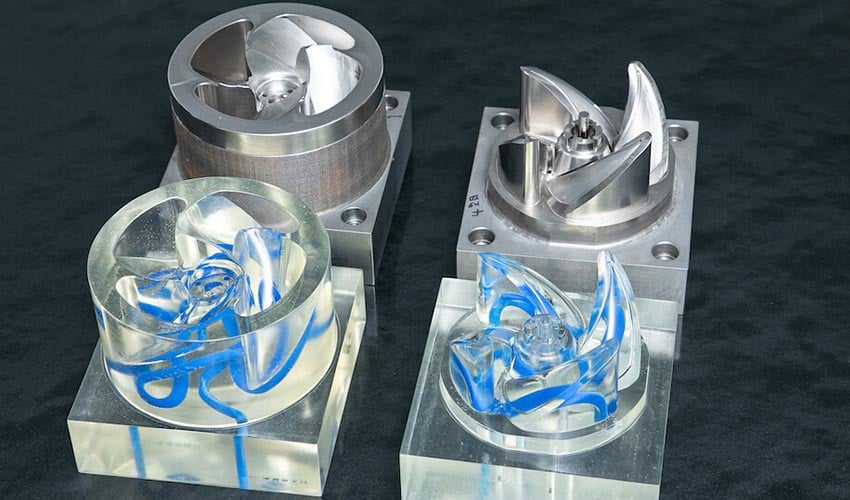

Cooling Optimization

Conformal cooling and baffle design for cycle-time reduction.

Material Expertise

ABS, PC, PA, POM, PP, high-temp and glass-filled resins.

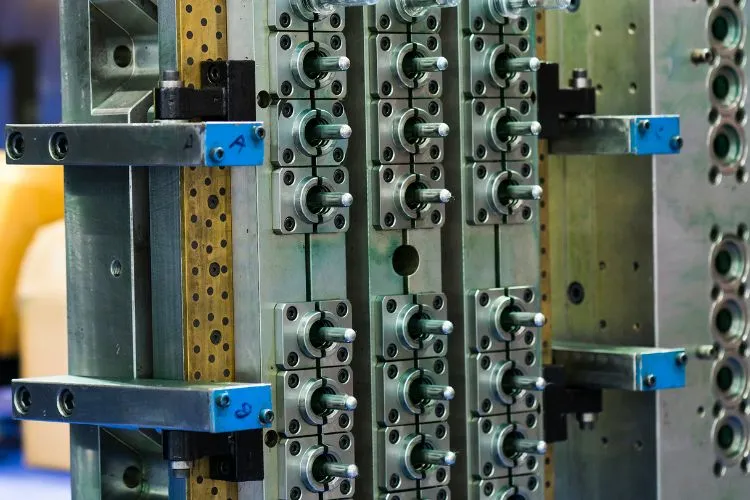

Multi-Cavity & Family Tools

Balanced filling with rigorous tolerance control.

Surface & Tolerance

SPI finishes, EDM textures, tight tolerances to spec.

Maintenance & Spares

Standardized components and service kits for uptime.

Case Study — High-Cav Mould: 28% Cycle Time Reduction

Challenge: Long cycles and hotspots

Solution: Conformal cooling + gate redesign

Outcome: 28% faster cycles, 12% energy savings

Faster Cycles

Optimized cooling and ejection cut cycle times by 15–30%.

Lower Cost/Part

Tooling and resin strategies that reduce scrap and energy load.

Built to Last

Wear-resistant steels and inserts that extend tool life.

FAQs

What lead times can you hit?

Typical new tools: 4–10 weeks depending on complexity and cavity count.

Can you refurbish or optimize existing tools?

Yes—cooling, gating, and inserts are common upgrade paths.

What tolerances do you hold?

Tooling tolerances per drawing; production tolerances validated during trials.

Do you support PPAP/IATF documentation?

Yes—on request for automotive and other regulated sectors.

Ready to bring your product or process to life?

Let’s discuss your project today — from prototypes to production-scale automation.