Real Solutions. Measurable Impact.

From rapid prototyping to AI-powered business launch, see how we’ve helped clients innovate faster.

Case Study: BlueSky Wholesale

Challenge

High barriers to entry: Regulations around advertising and payments made launching online risky and complex.

Manual processes: Customer onboarding, order handling, and service were slow and inconsistent.

Conversion struggles: Their early digital presence lacked a compelling user journey, resulting in low sign-ups and poor engagement.

Our Solution

We partnered with BlueSky to deliver an end-to-end launch strategy:

High-Converting Wholesale Website

Built a custom website optimized for B2B conversion.

Streamlined catalog browsing, account requests, and checkout flows.

AI-Powered Automation

Deployed an AI sales assistant for 24/7 customer interaction.

Automated customer onboarding, FAQs, and support ticket routing.

Regulation-Safe Marketing

Designed and managed ad campaigns tailored for restricted categories.

Navigated compliance challenges with copy, targeting, and landing page design.

Payment Infrastructure

Integrated secure, compliant payment solutions despite restrictions.

Reduced friction and built trust with wholesale buyers.

Outcome

Scaled from zero to $100k+ monthly revenue in 6 months.

5× increase in qualified wholesale sign-ups.

70% support ticket deflection via AI automation.

Strong compliance foundation, protecting the business from risk while enabling growth.

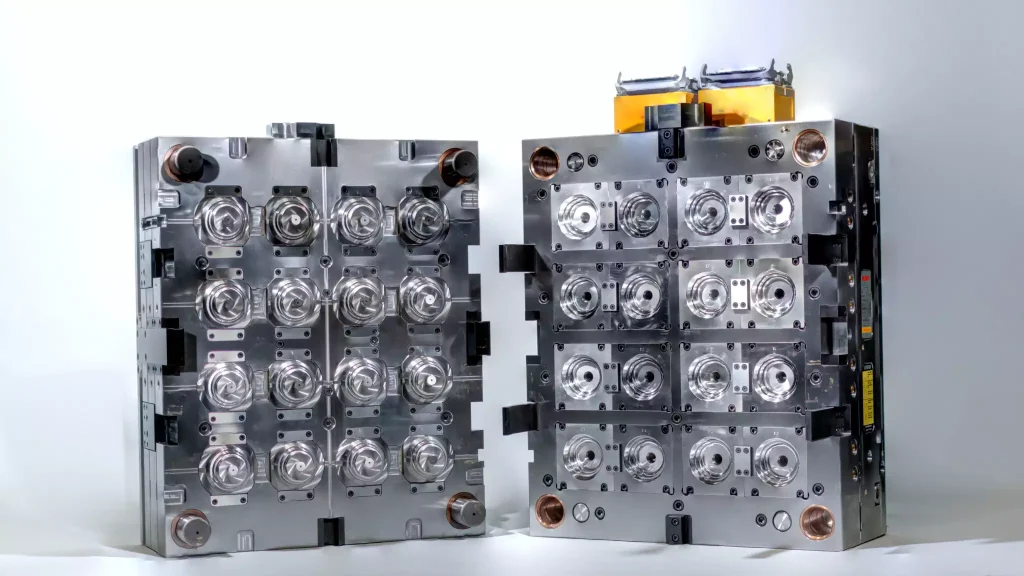

Case Study: Semiconductor Moulding

Challenge

High Scrap Rates: Existing mould geometry was producing inconsistent fills and leading to frequent part defects.

Lengthy Changeovers: Traditional setup and tooling adjustments took hours, slowing throughput and creating bottlenecks.

Escalating Costs: Scrap material and downtime were costing the client over $3M annually in wasted output and lost efficiency.

Our Solution

Quattro International designed a two-pronged solution:

Mould Geometry Redesign

Re-engineered tool geometry for more consistent material flow.

Reduced stress points to improve reliability across multiple production runs.

AI-Powered Predictive Maintenance

Implemented sensors and machine learning models to monitor wear in real time.

Shifted maintenance from reactive (after failures) to predictive (before downtime).

Process Optimization

Streamlined changeover procedures with modular tooling.

Reduced setup complexity, enabling faster production restarts.

Outcome

40% reduction in rejects, cutting scrap dramatically.

35% faster changeovers, leading to higher machine availability.

Annual savings of $3M+, with project ROI achieved in just 9 months.

Case Study: Class II Medical Device — Zero Deviations at Launch

Challenge

Tight Validation Timeline: The client had less than 90 days to complete IQ/OQ validation and move into production.

High Regulatory Risk: Any deviation could trigger rework, audits, or launch delays.

Traceability Requirements: Full documentation across equipment, processes, and risk controls was mandatory.

Our Solution

Quattro International partnered with the client to accelerate validation without compromising compliance:

Parallel IQ/OQ Preparation

Conducted installation (IQ) and operational qualification (OQ) preparations in parallel rather than sequentially.

Used pre-approved templates to reduce documentation cycle times.

Risk-Based Sampling

Applied statistical sampling focused on high-risk areas instead of exhaustive testing.

Reduced test volume while maintaining regulatory confidence.

Compliance-First Documentation

Built traceability matrices that linked every requirement, risk, and test outcome.

Delivered complete audit-ready documentation from day one.

Outcome

On-Time FDA Approval: Device launched on schedule, avoiding costly delays.

Zero Deviations: No corrective actions required throughout validation.

Full Traceability: End-to-end compliance ensured audit readiness.

Case Study: High-Cav Mould — 28% Cycle Time Reduction

Challenge

Long Cycle Times: Cooling delays extended each cycle, limiting output.

Hotspot Formation: Uneven thermal distribution led to part warpage and inconsistent quality.

Energy Inefficiency: Prolonged cooling and reheating cycles consumed unnecessary power.

Our Solution

Quattro International redesigned the mould and optimized thermal management to unlock efficiency gains:

Conformal Cooling Channels

Integrated advanced conformal cooling geometry via additive tooling.

Eliminated hotspots by ensuring uniform heat dissipation across all cavities.

Gate Redesign

Modified gate placement to improve resin flow and reduce shear.

Achieved more balanced filling, lowering part stress and cooling requirements.

Process Simulation & Validation

Used flow simulation to model thermal behavior before machining.

Conducted pilot runs to fine-tune cycle times and energy draw.

Outcome

28% Faster Cycles: Significant throughput improvement without sacrificing quality.

12% Energy Savings: Lower cooling demand reduced overall energy consumption.

Improved Part Consistency: Fewer rejects and higher dimensional stability.

Our Approach is Different

- Dedicated support at every stage

- Industry-specific expertise

- Rapid delivery without compromising quality

- Scalable solutions from prototype → full production

Ready to bring your product or process to life?

Let’s discuss your project today — from prototypes to production-scale automation.