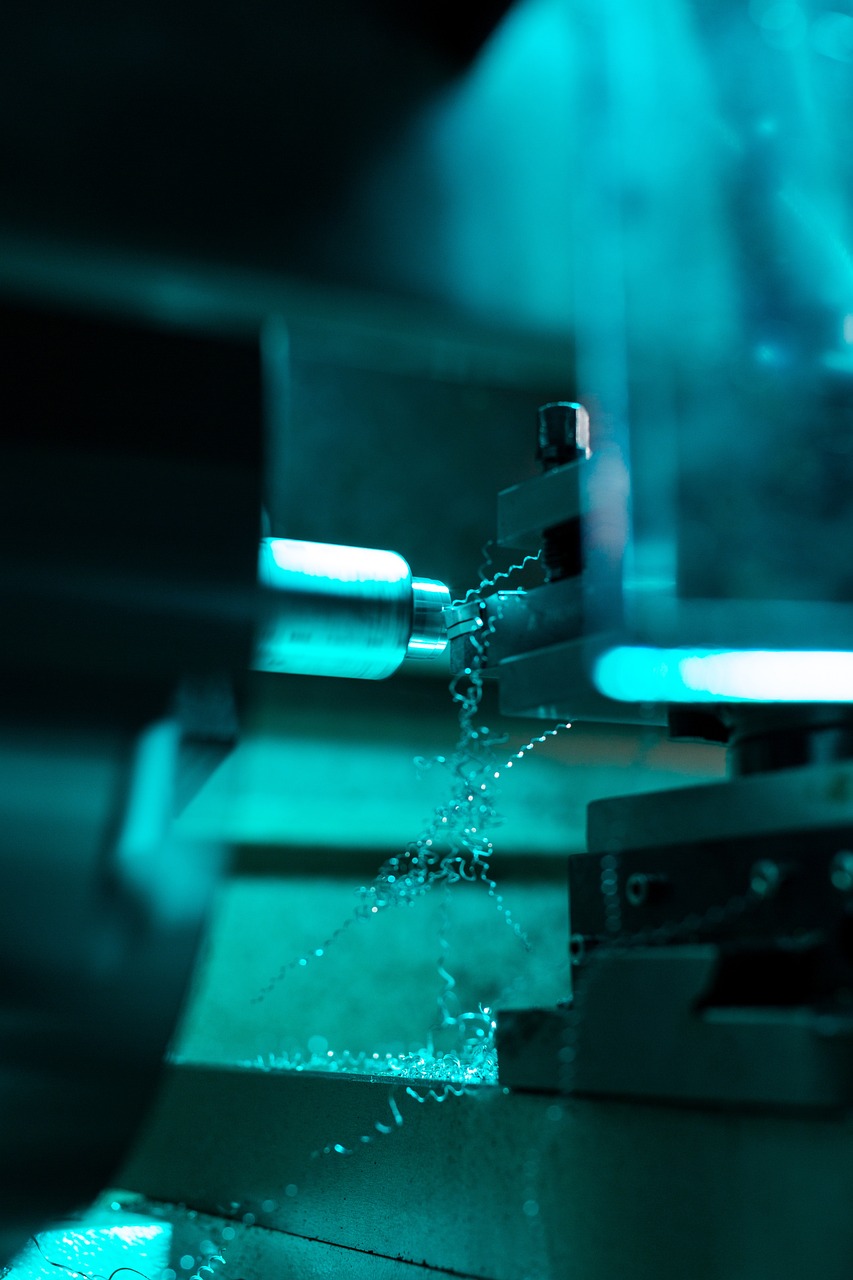

Medical Device Tooling

ISO-ready tooling and process documentation for regulated manufacturing — built for consistency, traceability, and validation.

Typical response time: within 24 hours.

Regulatory & Technical Capabilities

Design Controls

Aligned with ISO 13485 and FDA expectations.

Material Compliance

USP Class VI, ISO 10993 guidance support.

Documentation

Traceability packs, lot control, device history records.

Process Validation

DQ/IQ/OQ/PQ with protocols and reports.

Metrology

GR&R, capability studies, and inspection plans.

Packaging & Sterilization

Supports EtO/Gamma requirements.

Case Study — Class II Device: Zero Deviations at Launch

Challenge: Tight validation timeline

Solution: Parallel IQ/OQ prep + risk-based sampling

Outcome: On-time approval, zero deviations, full traceability

Validation Ready

Supports DQ/IQ/OQ/PQ with complete traceability.

Clean Manufacturing

Materials and finishes aligned to biocompatibility needs.

Risk Managed

FMEA and change control integrated from day one.

FAQs

Do you work under ISO 13485?

Yes—our approach aligns to ISO 13485 and risk-based principles.

Can you support FDA submissions?

We provide the tooling/process documentation needed by your RA/QA team.

What about biocompatible materials?

We help select materials and finishes consistent with your biocompatibility plan.

Do you supply PPAP for medical?

Where required, we mirror similar documentation conventions for medical equivalents.

Ready to bring your product or process to life?

Let’s discuss your project today — from prototypes to production-scale automation.